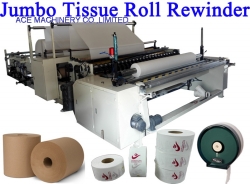

Full Automatic Toilet Paper Kitchen Towel Maxi Roll Making Machine with Lamination

Full Automatic Toilet Paper Maxi Roll Machine Manufacturer in China

This full Automatic toilet paper maxi roll making machine for sale is with automatic core loading unit, point to point lamination unit, embossing unit and perforation unit.

It is a multifunctional tissue paper rewinder machine to make toilet paper, maxi roll, JRT rolls, kitchen towel and airlaid nonwoven rolls. It can connect with automatic maxi roll band saw cutting machine and automatic maxi roll packing machine to make full automatic maxi roll production line.

The automatic maxi roll making machine is for sale with good price by China toilet paper machinery maker ACE MACHINERY.

Advantages of this toilet paper maxi roll machinery:

1 Fully automatic, labor saving

2 With point to point glue lamination

3 Mutifunctional tissue paper rewinding machine for toilet paper, kitchen towel and maxi rolls 3 products in 1 machine.

4 high speed 250 m/min

5 Easy maintenance and reliable.

6 Advanced technology.

7 Automatic loading the carbon cores.

8 Finished roll diameter 60-350mm.

Quick details:

1 Mother roll width 1200mm – 4000mm

2 Lamination system.

3 Embossing unit

4 Separator motor drive

5 Can connect to maxi roll logsaw cutting machine

|

Model |

|

|

ACE-TRM |

|||||||||

|

Output type |

||||||||||

|

Mother roll width(mm) |

1300 |

1800 |

2000 |

2200 |

2400 |

2600 |

2800 |

3000 |

4000 |

Customized |

|

Mother roll diameter (mm) |

Up to 2000mm or customized |

|||||||||

|

Machine speed |

250 m/min |

|||||||||

|

Raw paper |

13-20g/m2 2-ply, 16-45g/m2 1-ply, wooden pulp paper or MG paper or nonwoven airlaid. Other sizes please specify. |

|||||||||

|

Finished roll diameter |

60-350mm. |

|||||||||

|

Unwind section |

a. With Two jumbo roll back stands. b. Driven by separate reduction motors, not belts and chains. c. Jumbo Roll diameter: Max. Ф1200mm (Other size, please specify). d. Core diameter: Ф76mm. e. Pneumatic loading jumbo rolls automatically. f. With 2 sets of cone pulleys hand wheels to control jumbo roll web tension.(Electrical type is optional) g. Synchronism paper feeding unit. With wide flat belts for feeding the jumbo roll. h. With hand wheel for adjusting each jumbo roll to the left or right.(Electrical type is optional) |

|||||||||

|

Rewind section |

a. With core tank for automatic feeding paper cores. b. Core diameter adjustable. c. With automatic perforation system: Perforation size is adjustable. d. Perforation system can be switched OFF or switched ON. Able to produce rolls with perforation and without perforation. e. With automatic finished roll tail trimming and sealing system to seal the logs with straight glue lines. f. It can convert 1 or 2plies jumbo roll of difference gsm paper. g. With thickened floor standing wallboard structure to ensure high speed running no vibration. |

|||||||||

|

Embossing section |

a. With 2 sets of steel-to-rubber full embossing units. (Embossing pattern provided by the buyer or recommended by us.) b. Controlled by level-type pneumatic cylinders copied Italy design. Most other companies’ machines embossing units are controlled by screws or direct-pressing cylinders which make it very difficult to control the web tension and the paper will stick to the rollers, if you are not experienced enough, it will be big problem for you. They mostly put the embossing units on the steel frame, when the machine is running at high speed; it will definitely vibrate very much. c. Embossing tension is adjustable.(Micro adjustment.) so that the machine can work with papers with different quality and different gsm. d. Floor standing wallboard structure (thickened full steel plate support structure); to make sure the machine will NOT vibrate when running at high speed. Other companies adopt half steel frame for upper part and half steel part for lower parts, which is weak structure. e. Crown on the embossing rolls. f. Heavy chrome coating. g. Famous brand bearings for embossing rolls, perforation rolls, etc. |

|||||||||

|

Point to point Lamination system |

a. With one complete sets of point to point lamination units. b. The whole design is copied Italy design. c. Heavy chrome coating roll d. Micro-adjustment of nips between the steel roll e. Anilox roll for glue applicant. f. Controlled by cylinders g. Each lamination unit controlled by an independent reducer. When the machine stops, the motor will start running to rotate the anilox roll to prevent it getting dry. |

|||||||||

|

Tension control |

Speedless Tension control unit to fit the machine for paper of different quaity and different gsm. With automatic web guiding system. With automatic web tension control system. |

|||||||||

|

Counting |

Automatic counting unit |

|||||||||

|

Emergent stop |

Emergent stop unit to inspect any paper breaks, paper jams. |

|||||||||

|

Power |

7.5Kw for main motor (3-phase AC380V 50Hz or customized) |

|||||||||

|

Machine size |

6x2-405x2m |

|||||||||

|

Weight |

6T |

|||||||||

|

Videos and photos available. |

||||||||||