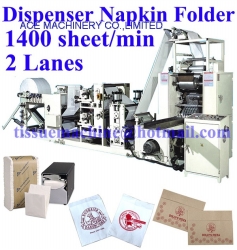

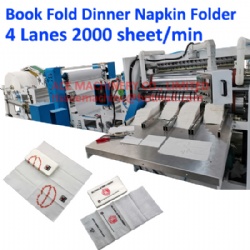

4Lanes Low Fold Dispenser Napkin Machine

China manufacturers of high speed lowfold dispenser napkin folder

Below video of Low Fold Dispenser Napkin Machine for reference. Please check out this video link to watch the video directly. Youtube: https://youtu.be/DnEr9oEloHM

Technical parameter: Please check out this link for other high speed napkin paper machines.

A. Jumbo roll stand

1.Parent roll specification: 60-35g/m2 1-ply; 13-25gsm 2 plies tissue paper (virgin paper or 100% recycled tissue paper or nonwoven). Others to be customized.

2.Parent roll size: ≤Φ1600 x 840mm(210mm * 4lanes = 840mm). Diameter x Width. Other sizes can be customized.

3.Core inner diameter: 76mm

B. Feeding Section

1. With One jumbo roll stand;

2.Pneumatic cylinder control

3. Stepless adjusting speed to control web-tension of paper.

4. Web tension is adjustbale by hand wheel. Or tension adjustment.

5. With pneumatic system to automatically load jumbo rolls.

6. Floor-standing thickened wallboard steel frame structure to ensure high speed running less vibration.

7. Use Japan NSK bearings for main rollers.

C. Embossing Section

1. With one set of steel to paper embossing unit. (Embossing pattern provided by client or recommend by us)

2. Mechanical press type.

3. Floor-standing thickened wallboard steel frame structure to ensure high speed running less vibration.

4. Use Japan NSK bearings for main rollers.

D. Printing Section (advanced design copied Italy technology.)

1. With 2 colors flexo-graphic printer section.

2. Closed chamber printing system, equipped with doctor blades to ensure high quality printing.

3. Printing unit with driven by timing belts to make printing more precise.

4. Simple and easy adjustment of horizontal and longitudinal registration by turning hand wheel.

5. With automatic printing roller disconnection device during machine stop. If the machine stops, the roller will automatically disconnect with the printing unit, controlled by pneumatic system.

6. The printing plate roller can be adjustable or disassembled from the printing unit, much easier for the operator to attach the printing rubber plates or clean the roller.

7. With printing ink reservoir for reserve dropping ink and avoid ink dropping on machine or place to keep environment clean.

8. Floor-standing thickened wallboard steel frame structure to ensure high speed running less vibration.

9. Use Japan NSK bearings for main rollers.

E. Folding Section

1.Final napkin products

Open napkin size: 304x210 mm

Folded napkin size: 152x105 mm

2. Folder type: special 1/4 or 1/6 fold, L-fold, dispenser fold and vacuum fold type.

3. Synchronizer for feeding paper

4. With 4 lanes delivery. (single lane or double lanes machine is available.)

5. Capacity: about 400-500 piece/min/lane x 4lanes = 1600-2000 pc/min, depending on paper quality, gsm and workers operation etc..

6. With automatic counting unit. With tissue pop up every count.

F. Control system

1. With JOG function, for easy threading the paper through the embossing unit, printing unit etc.

2. With emergency stop function. You can stop the machine in any cases of emergency.

3. With auto sensors for detecting paper breaks or used up. Machine will automatically stop if paper breaks or used up.

4. Famous brand motor.

5. Power:about 4.5kw for main motor, 7.5KW for the pump. (3-phase AC220V 60Hz or customized)

6. Pressure: 0.5MPa.

7. Machine size: 6x1.5x1.7(M)

8. Weight: about 4500 kg