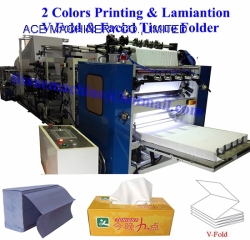

Fully Automatic Z N Multi Fold Interfold Paper Hand Towel Line with Auto Transfer to Packing

Fully Automatic Z N Multi Fold Interfold Paper Hand Towel Production Line with Auto Transfer

Introduction of this paper towel machine line:

As one of the leading fully Automatic Paper Hand Towel Machine manufacturers and suppliers in China, ACE Machinery has innovated this patented high quality, high speed, trouble-free, reliable, excellent quality Automatic Paper Hand Towel Machine Line to manufacture the paper hand towels with high automation. It can significantly increase the production efficiency but reduce huge labor costs.The whole automatic paper hand towel machine line consists of automatic paper towel machine, automatic paper hand towel log saw cutting machine and automatic paper hand towel packing machine, A to Z fully automatic without worker. It is an ideal paper towel machine for the paper towel manufacturers.

Advantages of this full automatic Z Fold Paper Hand Towel Machine with Auto Transfer to Automatic Paper Hand Towel Packing Machine:

1 Fully automatic with auto transfer to automatic paper hand towel log saw machine.2 High speed up to 1000 sheet/min/lane. 40 pack/min.

3 Connect with fully automatic paper hand towel packing machine.

4 Labor saving.

Basic technical parameters:

|

|

|

Fully Automatic Z Fold Paper Hand Towel Interfold Machine |

|

|

Jumbo roll size |

≤1710mm x Φ1500mm;(Other size available.) |

|

Folding Type |

Z fold, N fold and multi fold interfold paper towels. |

|

Paper Towel size |

open size: 230±2mm x (210-220) mm. Folded size: 76±2mm x (210-220) mm. |

|

|

|

ACE-ZT Auto Transfer System for Interfold Paper Hand Towel Machine. |

|

| Working Principle |

Fully auto transfer the paper hand towel logs to the automatic paper hand towel log saw and paper hand towel packing machine |

|

Log specification |

13-75 g/m²1 or 2ply facial tissue. or Other |

|

Paper Hand Towel Log size: |

width ≤1800mm. |

|

Log auto transfer speed: |

12 log/min, depends paper hand towels |

|

|

|

ACE-ZLS Fully Automatic High Speed Z Fold Paper Hand Towel Log Saw Cutting Machine |

|

|

Machine structure |

Single lane logsaw cutting. |

|

Applicable material: |

Z N multi fold paper hand towels or facial tissues |

|

Cutting speed |

30-180 cut/min, depends on tissue quality etc. |

|

Cutting sizes ranges of paper hand towel logs: |

L 60-300mm W 60-250mm H 25-120mm adjustable or customized |

|

|

|

ACE-FZP Fully Automatic Z N Multi Fold Single Bag Packing Machine |

|

|

Packing format |

Fully automatic packing single bag of Z N multi fold paper hand towels |

|

Packing speed |

about 30 - 40 pack/min, depends on tissue sizes. |

|

Packing scopes(final product): |

L = 200mm-300mm W = 110mm-250mm H = 60mm-115mm other sizes to be customized. |

|

|

|

Below video of Fully Automatic Z N Multi Fold Interfold Paper Hand Towel Machine Line with Auto Transfer to Packing for your reference:

More details of this Fully Automatic Z N Multi Fold Paper Hand Towel Machine Production Line with Auto Transfer. please refer to below:

ACE-N230-7L High Speed N Z Multi Fold Paper Hand Towel Machine

A. Jumbo roll

a. Jumbo roll specification:18-45g/㎡ * 1ply virgin tissue paper or other tissues. Other sizes, please specify.b. Jumbo roll size: ≤1710mm x Φ1500mm.(Other size available.)

c. Jumbo roll core diameter:Φ76mm.

B. Product size

a. Finished product: Z fold, N fold and multi fold interfold paper towels.

b. Z fold paper towel open size: 230±2mm x (210-220) mm.

c. Z fold paper towel folded size: 76±2mm x (210-220) mm.

d. Fixed cutoff size (cylinder size) is 230mm. other size available, please specify.

e. Folding type: Z fold, interfold and Vacuum folding type.

C. Paper feeding

a. With 1 back stands, controlled by pneumatic cylinders.b. The jumbo roll driven by an independent motor, NOT belt.

c. With mechanical auto web tension control system.

d. Synchronism paper feeding unit.

e. With hand wheel for each jumbo roll to adjust the jumbo roll to the left or right.

f. Pneumatic loading Jumbo roll.

g. Equipped with optical sensor to detect the jumbo roll. The machine will auto alarm when the jumbo roll is used up.

D. Folding unit

a. Automatic left-right stagger counting unit or ink mark.b. Independent Floor standing wallboard structure (thickened full steel plate support structure), to make sure the machine will NOT vibrate when running at high speed. Other companies adopt half steel frame for upper part and half steel part for lower parts, which is weak structure.

c. Add oil in manual.

d. With stepless-adjustment hand wheels to control web tension.

e. Without on-line slitters.

f. Equipped with fully automatic system to transfer the Z fold paper towel tissue logs to the conveyor of the automatic paper towel cutting machine and cut into desired size paper towels and then auto transfer the paper towels to the automatic paper towel packing machine.

E. Embossing unit

a. With 1 set of steel-to-steel embossing unit.b. Strong structure and design.

c. Heavy chrome coating roll.

d. Controlled by screws.

e. The gears of the embossing rollers are inside a closed lubrication cabinet, always with oil, to extend the life time.

F. Control system

a. Machine Speed: about 1000 piece/min/lane x 7 lanes. Depends on paper quality, workers etc.b. Speed of production is controllable.

c. Main motor control by inverter

d. Automatic left-right stagger counting system or ink make, each stack of 100 pieces, 150pieces etc.

e. Machine will automatically stop if paper break or paper jams.

f. Power: about 7.5KW for main motor 3-phase AC380V 50HZ or customized.

g. With Taiwan vacuum pump, about 22KW. (Taiwan brand)

h. Vacuum pump for adsorption (included in quotation.)

i. Air pressure: 0.5Mpa(buyer supplied)

j. Machine weight: about 10T.

k. Machine size: about 9000x2300x2100mm.

l. Important parts:

Japan Omron sensors.France Schneider electronics like contactors, relay and breakers.

The best China bearings. (Japan NSK or Sweden SKF bearings for the main rollers.).

Taiwan vacuum pump, less noise and power.

Jiangsheng brand motors made in China.

paper towel machine with auto transfer

ACE-ZT Auto Transfer System for Interfold Paper Hand Towel Machine.

A. Log width

a. Log specification 13-75 g/m² 1 or 2ply facial tissue. Other requirements to be specified.b. Log size: width ≤1800mm.

A. Control system

a. Log auto transfer speed: 12 log/min

b. Speed of production is controllable.

c. PLC control

d. Servo motor control.

e. Automatic sense every log by the ink mark of every count.

f. Speed can be synchronized with the automatic paper hand towel interfolder machine.

g. Number of Sheets/pack- 50 -200 pieces.

h. Power: 3-phase AC380V 50HZ.

i. Air pressure: 0.6Mpa(buyer supplied)

j. Machine weight: about 2000kg.

k. Machine size: 3000x2000x1800mm.

ACE-ZLS Fully Automatic High Speed Z Fold Paper Hand Towel Log Saw Cutting Machine

Main structure: single lane cutting.Applicable material: Z N multi fold paper hand towels or facial tissues

Designed speed: 200 cut/min

Working speed: 80-180 cut/min, depends on tissue quality etc.

Infeed channel: With 1 piece of infeed conveyor 3 meters length.

Cutting delivery system: Independent servo control and driving.

Cutting sizes ranges: L 60-300mm adjustable

W 60-250mm

H 25-120mm

Cutting tolerance length: ±1mm

Cutting tolerance vertical: ±1.5mm

Output delivery: During the whole paper hand towel log saw cutting process, the paper hand towel tissue logs are pressed by left belts + right belts to prevent the tissue log getting slippery and guarantee every cut accurate cutting.

Adopt 2 servo motors to control the timing belts before the circular blade cutting and after the circular blade cutting .

Circular blade outer diameter: 610mm

Blade grinding/sharpening system: Automatically and pneumatically grinding/sharpening, grinding/sharpening time and interval parameters can be set in the touch screen. For example, you can set it to sharpen for 1 seconds every 30 minutes or every 50 cuts.

Cutting system: 360° rotating cutting. (Not like other companies machines, the cutting system is only up-and-down cutting.)

Trimmed waste removal system: With log edge trim function. The trimmed waste can be automatically blew away by air.

Control system:

PLC programmed control,Inverter for variable frequency speed control,

Touch screen for operation

Servo driving: adopt 2 servo motors to control the timing belts before the circular blade cutting and after the circular blade cutting .(But other companies’ machines use only one servo motor or NO servo motor, controlled by only inverter, which cannot guarantee accurate cutting.)

Air compressor: 4-8kg/cm2pa, supplied by customer.

Installed Power: 3phase 380v 50hz. total about 6.4kw

Servo system power: about 2 kw

Rotate motor power: about 2.2kw

Blade motor power: about 2.2kw

Machine weight: about 2T.

Machine dimension: about 5x1.9x1.95m LxWxH. Floor plan refer to below.

ACE-FZP Fully Automatic Z N Multi Fold Single Bag Paper Hand Towel Packing Machine

Technical parameters:

1- Applicable tissue: Z fold interfold paper hand towel.2- Fully automatic packing single bag of Z N multi fold paper hand towels.

3- Design speed 20 - 40 pack/min.

4- Stable packing speed: about 30 - 40 pack/min, depends on tissue sizes.

5- Packing scopes(final product): L = 200mm-300mm

W = 110mm-250mm

H = 60mm-115mm

6- Film roll diameter: ≤600mm.

7- Film roll guiding method: Automatic guiding the film.

8- Equipped with automatic perforation system to make perforated dotted lines on the paper towel package so that the clients can easily open the paper towel package and pull out the paper towels out of the bag.

9- Film material: CPP or PE films, pre-made bags(roll-shape).

10- Recommended film material: PE with thickness 0.04mm - 0.05mm.

11- Power: total 17.5KW heating power 1.2kw, 3phase 380v 50hz.

12- Applicable current: +/-10%.

13- I/O input (VDC): 24VDC.

14- I/O output (VDC): 24VDC.

15- Control system: Servo motor control

PLC control

Touch screen for data setting.16- Required air pressure: 0.5-0.7 mpa.

17- Air consumption: 300 L/min.

18- Machine dimension: L4120mm * W2030 mm * H1930 mm.

19- Machine weight: about 3600kg.

Final z fold paper towel made by this Fully Automatic Z N Multi Fold Interfold Paper Hand Towel Line with Auto Transfer to Packing for reference: